MERV HUGHES, SLIM DUSTY, PENTRIDGE PRISON & AN AUSTRALIAN DREAM

Long before Brunswick, in Melbourne’s north, became a trendy suburb filled with latte drinking hipsters, it was a working class area largely famous for textiles manufacturing and the local footy team.

It was here in 1914 that a young migrant from Cheshire in England, Fred Townley, dreamt of a new beginning and set about designing his own history by starting Townley Drop Forge.

Fred was a first class blacksmith who had worked on the English railways for more than 30 years before emigrating to Australia with his wife Eleanor and daughter Freda in tow.

With the production of brass belt buckles and horse harnesses for the military, the forge became a huge success. Surviving two World Wars and the great depression of the 1930’s, it developed into a thriving family business as Fred introduced his son in law, Vernon Claringbould as manager.

By the late 1950’s, the forge was largely servicing the burgeoning auto industry with forged, welded and machined parts. The introduction of lifting products was expanded to include shackle links, lifting rings, eye bolts, eye nuts and more recently rigging screws and turnbuckles.

Roger Claringbould joined the family business in 1953 as a first year apprentice fitter and turner and with the death of his father Vernon in 1958 and grand father Fred in 1960, took on a larger than expected role as manager of the family business at the tender age of 22.

Roger remembers clearly the feeling of trepidation at taking on such a large responsibility. “The office lady was Mrs Hill and her husband Alex was the foreman. There were seven workers and the first thing I had to do was make sure they knew they were in a safe set of hands.”

“There was a back log of work and I remember thinking, I had the tiger by the tail but what do I bloody do now? I didn’t have a clue,” said Roger.

Rogers tenacity to continue his forbearers success in forging meant he thought long and hard about what he could do to keep the business alive.

“My philosophy was I must upgrade this equipment, I must see the opposition so I can get better equipment than they’ve got”

This belief in innovation led Roger to install new machinery and a larger oil fired furnace.

In 1970 Townley purchased two Massey drop hammers from Cyclone Forging Company and in 1971 installed the first Banning hammer in Australia using fuel oil furnaces for heating of raw material. Business was booming, however in 1975 a break-in and subsequent fire lit by vandals delivered a setback to Roger and his team.

“It was horrific,” Roger said, “There was probably only $5 in petty cash.”

The workers rallied around Roger, producing forgings as a new building was erected around them.

“There was no roof on the factory for three long months, everyone just kept working in the rain,” he said.

In 1976 Roger ticked off on the installation of the first induction heater to operate with the Banning hammer.

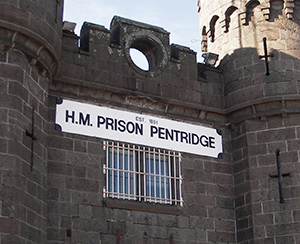

Roger recalls the labour shortage of the 1970’s and 1980’s. Father Brosnan, the Pastor at Pentridge Prison approached businesses in the area to help him with recently released prisoners to assimilate into the workforce, so Townley showed its moral conscience by providing ex Pentridge prisoners with valuable paid employment after they’d served their time.

One worker in particular, impressed Roger. “I’ve never met a man so strong. He’d carry these drums of hooks weighing in at 50kg each, one in each hand. I just remember the muscles,” he said with a laugh.

For a period of time in the 1980’s, Townley operated offices out of Sydney and it was here that an unexpected link to Slim Dusty’s chart topping song ‘I love to have a beer with Duncan’ came about.

The Duncan immortalised in Slim’s catchy tune is Duncan Urquhart, who owned a heat treatment business in Sydney and later served as manager of Townley’s Sydney office and factory which operated in the early 80’s.

The writer of the song’s lyrics and music, Pat Alexander, explains his inspiration for the song

“… the song had come straight out of the experience selling life insurance, and the only good thing that came out of those two horrible years was Duncan.”

“I was knocking on factory office doors in Sydney’s southern suburbs and the owner of a factory, Duncan, invited me in. In his late 40’s, he was free to talk and suggested we might do that down at the pub around the corner. That pub was the Town & Country Hotel in St Peters on Unwins Bridge Road.

“I went back to see Duncan three times before I twigged that he had no intention of buying any of my life insurance. He just enjoyed a yarn, but it was while driving home from the last of those sessions that the main verse came into being.”

Roger also recalls enjoying Duncan’s company over a meal and drinks at The Black Stump during his monthly visits to Sydney.

With the closing of the Sydney operations in 1986, Roger wanted to focus more on the original location in the ‘heart and soul’ of Brunswick.

Roger continued to innovate and keep abreast of changes in this old trade of forging however decided in 2002 it was time to sell up and take a back seat from the everyday running of the business.

He entrusted Townley to two cousins from Melbourne, Nigel Prince and Malcolm Stenniken.

“We set about fine tuning what was a solid business introducing more modern production and inventory systems said Nigel and Malcolm”.

Malcolm engaged with the production staff to introduce his skills as an engineer he had learnt in three previous businesses he had successfully built and run. ” It wasn’t easy, I had to earn my stripes introducing new production techniques, investing in new machinery, re training staff, and creating an environment for an apprenticeship scheme, which still functions today”.

“We were now working smarter not harder” Malcolm explains.

“It was a good fit said Nigel, Mal concentrated on manufacturing and production while I concentrated on sales and administration; it became obvious however that after a few weeks we were losing money; our customers had not received a price increase for several years while the cost of labour and materials had been steadily rising. It was up to me to go cap in hand to our customers to ask for a price increase and to determine what they wanted from us; the overwhelming majority said SERVICE!

We set about manning the phones for longer, creating a more accurate inventory system, hence no back orders and same day despatching of orders. This was costly, as we had to raise our inventory levels considerably. Next was to upgrade our advertising material to include brochures and most importantly the development of a new and easily accessible website. It was not without it’s headaches however it was well worth it! Mal and myself believe in Australian made”. Unfortunately Nigel had some health issues so the two cousins in turn decided to hand the reigns on to new owners Geoff Collinson and Rocky Galati in 2008″.

Now the focus of the forge is on the manufacture of high quality eye bolts, rigging screws, turnbuckles, lifting points and various custom forgings with a broad customer base including mining, construction, transport infrastructure and defence together with the development of new products.

The same entrepreneurial spirit of Fred lives on at Townley, with the workers and owners alike looking forward to the constant innovations that are happening within manufacturing and a larger focus on the future and sustainability.

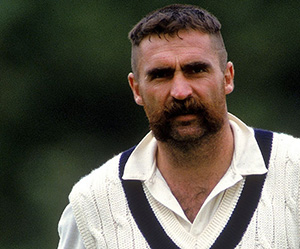

Part of that spirit has seen Townley engage former Australian Test Cricketer and Raconteur Merv Hughes as a brand ambassador.

Big Merv’s link to Townley is through one of the current owners Geoff Collinson, who was a longstanding Partner at “Big Four” accounting firm PricewaterhouseCoopers prior to retiring. Merv and Geoff played cricket together since the age of 17 at the Footscray Edgewater Cricket Club in Melbourne’s West.

Together they still administer the Club and Townley are a major sponsor. Last season the Club which boasts many former Australian and Victorian players won the Victorian Premier (Grade) Premiership with a resounding win over Essendon.

“We are extremely positive about the future of specialised Australian manufacturing and look forward to incorporating new ideas and ways of continuously improving our operations while also staying true to the entrepreneurial spirit that Fred established over 100 years ago,” said Geoff.

“Most recently we have updated the forge to include the latest technology in induction furnaces, this is cleaner, more efficient and sustainable for the longer term,” added Rocky Galati, joint owner of Townley Drop Forge.

All Townley products are manufactured in Australia to the highest possible standards for safety and reliability with full traceability and certification.

“You know you can trust Townley”.